How to organise a warehouse for space & efficiency using wire mesh dividers & more

How to organise a warehouse should always be at the front of one’s mind when managing or setting up a warehouse. The purpose of organisation in these environments is to maximise space and efficiency, which creates solid foundations for successful business operations.

Contents

How to organise a warehouse to maximise space

It is no secret that warehouse space is at a premium with the last 5 years seeing the most rapid increase in unit take-up in history. It is likely that this has stemmed from a shift in consumer purchasing behaviour towards e-commerce which looks to continue for the foreseeable future. With a recession looming, large capital expenditures, like a new warehouse, are less likely to be an option. Warehouse and project managers have no option but to make the most of the resources available and maximise space through organisation.

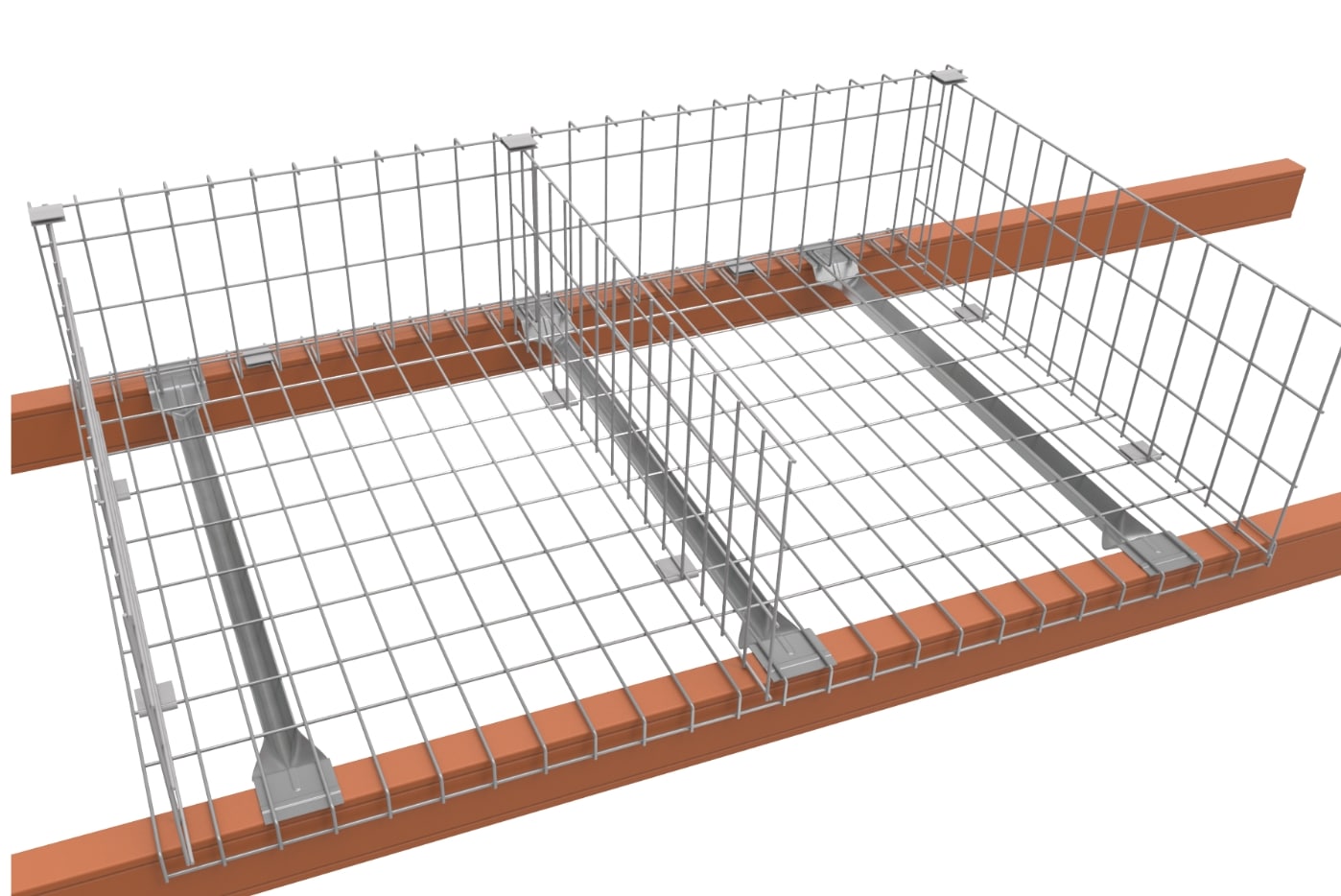

Make the most of your existing racking with anti-collapse extensions

QTS can help you maximise the available space through our rackGUARDIAN™ anti-collapse mesh extensions. Whilst the extension does not allow you to add more levels to it directly, it does mean that you can add a beam level at the top of the existing uprights whilst maintaining a safe environment.

Whilst adding one additional level is not going to solve all of your problems if you are looking to significantly increase your inventory, it is a cost-effective way to get that extra space to get you through periods of high demand. Implementing this idea across all your existing racking may surprise you with how much more storage space you have.

Using push-back racking safely…

As an expert in this industry, you have probably already heard about push-back racking. If you haven’t, it is essentially racking with rollers on so that you minimise the amount of space between the racking, allowing you to add more runs of racking but using the same amount of space.

Whilst QTS is not an expert in racking, we are the experts in mesh. As you can imagine, moving large amounts of stock on racking systems comes with health and safety concerns. To minimise risk, it is a good idea to add anti-collapse mesh to the rear of the push-back racking to avoid accidents. In addition, a wire mesh partition system, like storGUARD, is a great way to create a safe zone with limited access so that there is not a large number of pedestrians who could potentially get injured.

How to organise a warehouse to maximise efficiency

Making efficiencies within the warehouse is key to maximising profitability and makes meeting an increased demand much easier. Here are a couple of ways organisation can increase efficiency:

Keeping your shelving organised with warehouse rack dividers…

It may sound obvious, but it is easy to end up with an unorganised warehouse when you are running a high-paced logistics operation. A simple yet effective way to help with organisation is by adding dividers to your racking bays. Systems like the easyDIVIDER allow you to compartmentalise your bays into specific locations that can be labelled and logged with ease. This makes it far simpler for operatives to locate products and increase picking speed.

Making safety a priority…

When you are considering how to organise a warehouse, safety should be a top priority in any warehouse operation. Not only because there is a duty of care to the staff but also because high safety standards improve efficiency.

A minor accident, such as damage to pallet racking, can cause massive problems later down the line. A damaged pallet racking could lead to a whole aisle collapsing which will cause a large amount of downtime for cleaning up and will have a large cost associated with it. Avoid accidents by adding products like anti-collapse mesh, wire mesh partitions or upright and end-of-aisle protectors.

Share This: