Introducing the rackPROTECT Range: Pallet Racking Protection & Pedestrian Safety Barrier

Contents

Many companies only start looking at Pallet Racking Protection & Pedestrian Safety Barriers after an accident has happened. Skipping the cost in the short term can come back to bite them in the future with costly repairs, absent staff and downtime caused by damaged racking.

In the dynamic environment of modern warehouses, the safety of both personnel and stored goods is paramount. Efficiently managing a warehouse not only involves optimising space but also ensuring that every component of the operation is protected against potential hazards.

This is where the importance of advanced racking protection systems comes into play. QTS has a new range of Racking Protection products to improve safety and efficiency in warehouses. This includes End of Aisle Rack Protectors, Pallet Racking Upright Protectors, and Rack Deflectors, all at an affordable price.

The Need for Advanced Pallet Racking Protection & Pedestrian Safety Barriers

Warehouses are bustling places where accidents can happen frequently, particularly when forklifts and other heavy equipment are in use. One mistake can cause serious damage to both the racking systems and the valuable inventory they store. More importantly, it can put employees at risk of injuries.

Installing strong rack protection goes beyond just following safety rules. It involves creating a culture of safety and efficiency. This culture helps to keep both people and assets safe.

Features of QTS’s Racking Protection Range

End of Aisle Rack Protectors

End-of-Aisle Rack Protectors are vital for maintaining a safe and efficient warehouse environment. Their robust and highly visible design ensures that structural elements are safeguarded, risks are minimised, and operational flow is maintained. These protectors are an indispensable safety feature for any facility relying on racking systems for storage and inventory management. Pallet Racking Upright Protectors.

- Protection of Structural Integrity: Guards the racking system against impacts that can compromise its stability and safety.

- Inventory Safety: Minimises the risk of stock damage from accidental impacts, preserving valuable inventory.

- Enhanced Safety: Reduces the risk of accidents by providing a clear visual and physical barrier at the end of racking aisles to avoid upright damage.

- Cost Efficiency: Lowers repair costs and operational expenses by preventing damage before it occurs.

- Operational Continuity: Reduces downtime related to repairs and accidents, maintaining smoother, more efficient warehouse operations.

Pallet Racking Upright Protectors

Pallet Racking Upright Protectors are crucial for maintaining the safety and efficiency of warehouse and storage operations. Their robust design and strategic installation provide a critical defence against the daily wear and tear of industrial activities, ensuring that both personnel and products are protected. These protectors are a wise investment for any business looking to enhance the longevity and safety of their storage solutions.

- Structural Protection: Shields racking uprights from impacts that can cause structural damage or collapse.

- Inventory Safety: Minimises the risk of damage to stored goods, safeguarding inventory from accidents.

- Enhanced Safety: Increases overall safety in the warehouse by reducing the risk of racking system failures.

- Cost Efficiency: Reduces the need for costly repairs and replacements of racking components, providing long-term savings.

- Uninterrupted operations: Helps maintain smooth operations by minimising downtime related to damaged storage systems.

Rack Deflectors

Rack Deflectors are critical safety accessories designed to protect the structural integrity of warehouse racking systems. These compact protectors are strategically fitted to the front of racking uprights, providing robust protection against impacts from forklifts, pallet jacks, and other material handling equipment. Constructed from materials with high impact-absorbing properties, Rack Deflectors minimise the risk of damage, ensuring the longevity and safety of your storage solutions.

- Enhanced Protection: Reduces the likelihood of damage to racking systems, thereby preserving the integrity and stability of storage installations.

- Cost Savings: Prevents costly repairs and replacements of racking components by mitigating the effects of collisions.

- Operational Efficiency: The unobtrusive design does not compromise the storage capacity or operational space, maintaining efficiency in warehouse operations.

- Safety Improvement: Increases overall warehouse safety by reducing the likelihood of accidents caused by damaged racking

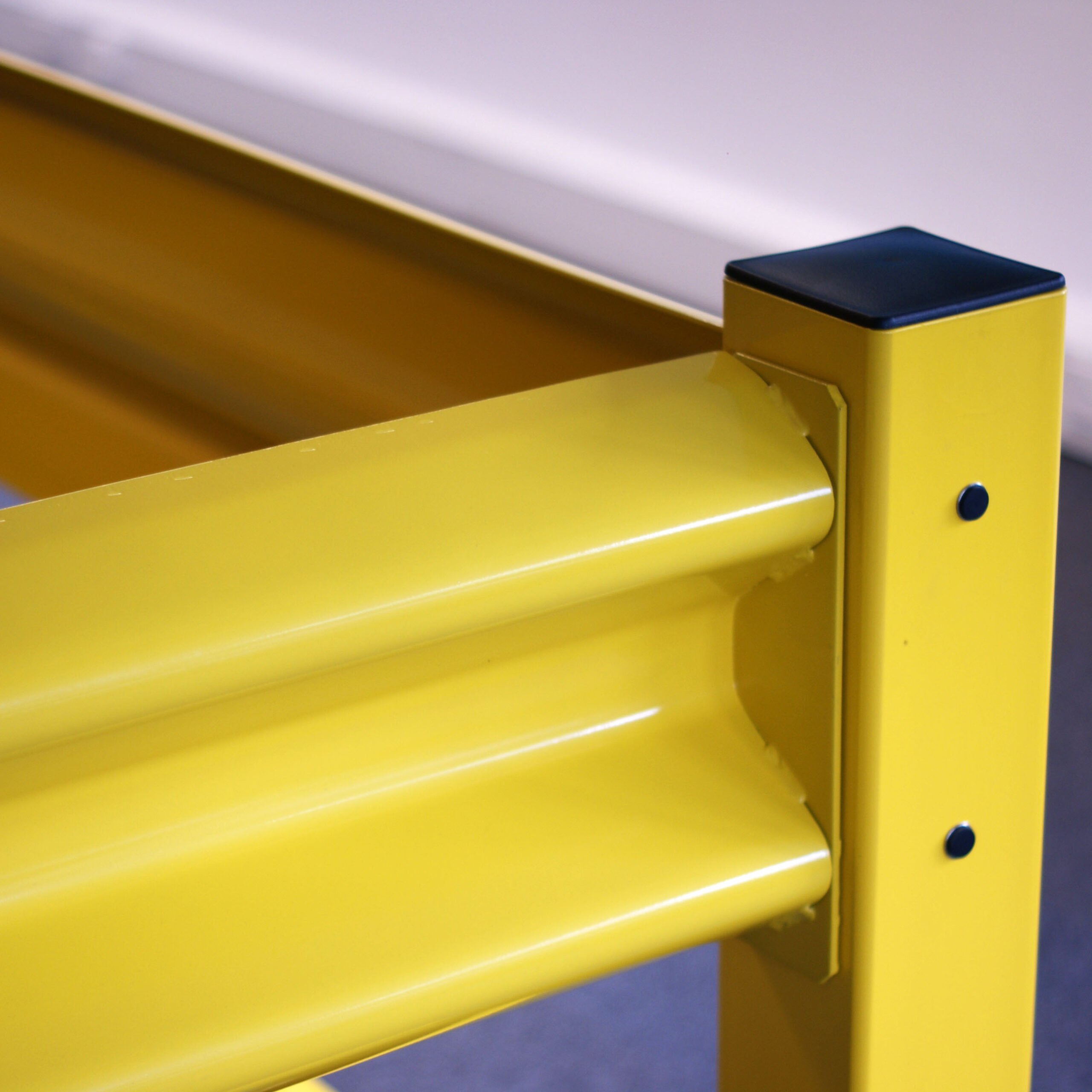

Pedestrian Safety Barriers

Pedestrian Safety Barriers are designed to enhance safety in warehouses and industrial areas. They clearly separate pedestrian walkways from areas where vehicles operate. The barriers create a physical barrier between pedestrians and vehicles helping to prevent accidents and injuries.

These barriers are available in single or double-rail designs and are made from collision-absorbing materials that are brightly coloured for optimal visibility. Customisable to fit any warehouse layout, they play a crucial role in minimising the risk of accidents and managing traffic flow within dynamic environments.

- Enhanced Pedestrian Safety: Significantly reduces the risk of accidents involving pedestrians and moving vehicles within the facility.

- Accident Prevention: Acts as a physical and visual barrier, preventing collisions and potential injuries.

- Traffic Management: Helps organise the flow of human and mechanical traffic, improving operational efficiency and safety.

- Adaptability: Easily integrated into existing safety systems, providing flexibility in layout changes and expansions

Don’t wait until the first sign of trouble to start thinking about the safety and efficiency of your warehouse.

If you need help with choosing products for your existing setup or new facility, our experts are here to assist you.

Share This: