Quick Stock

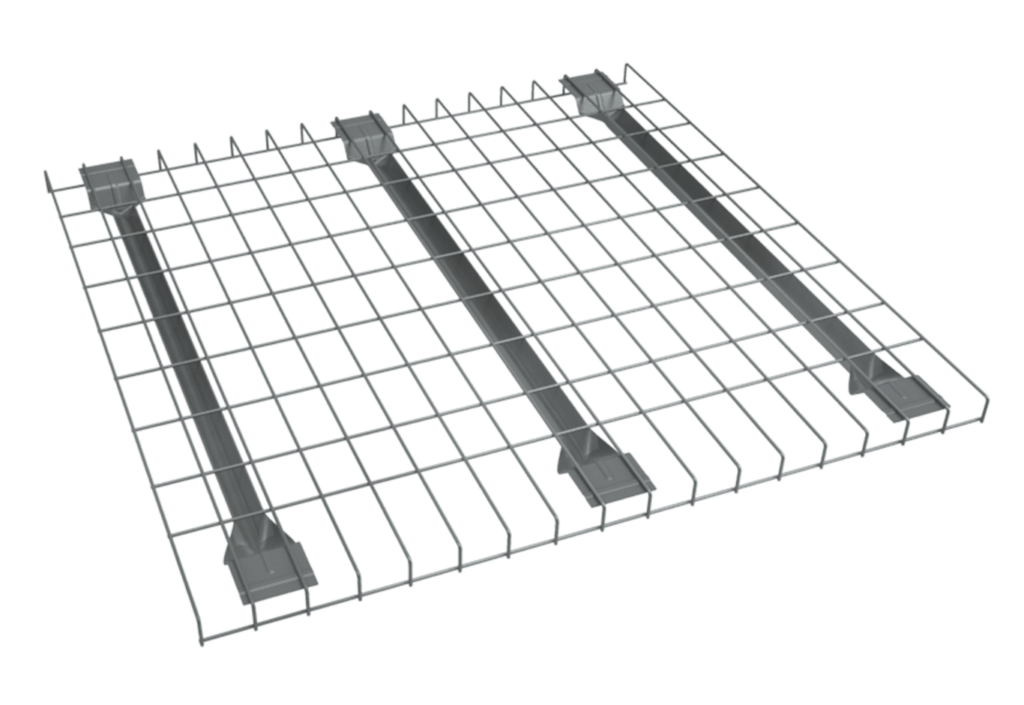

Powder-Coated Wire Mesh Decks

Quick delivery on powder-coated wire mesh decks

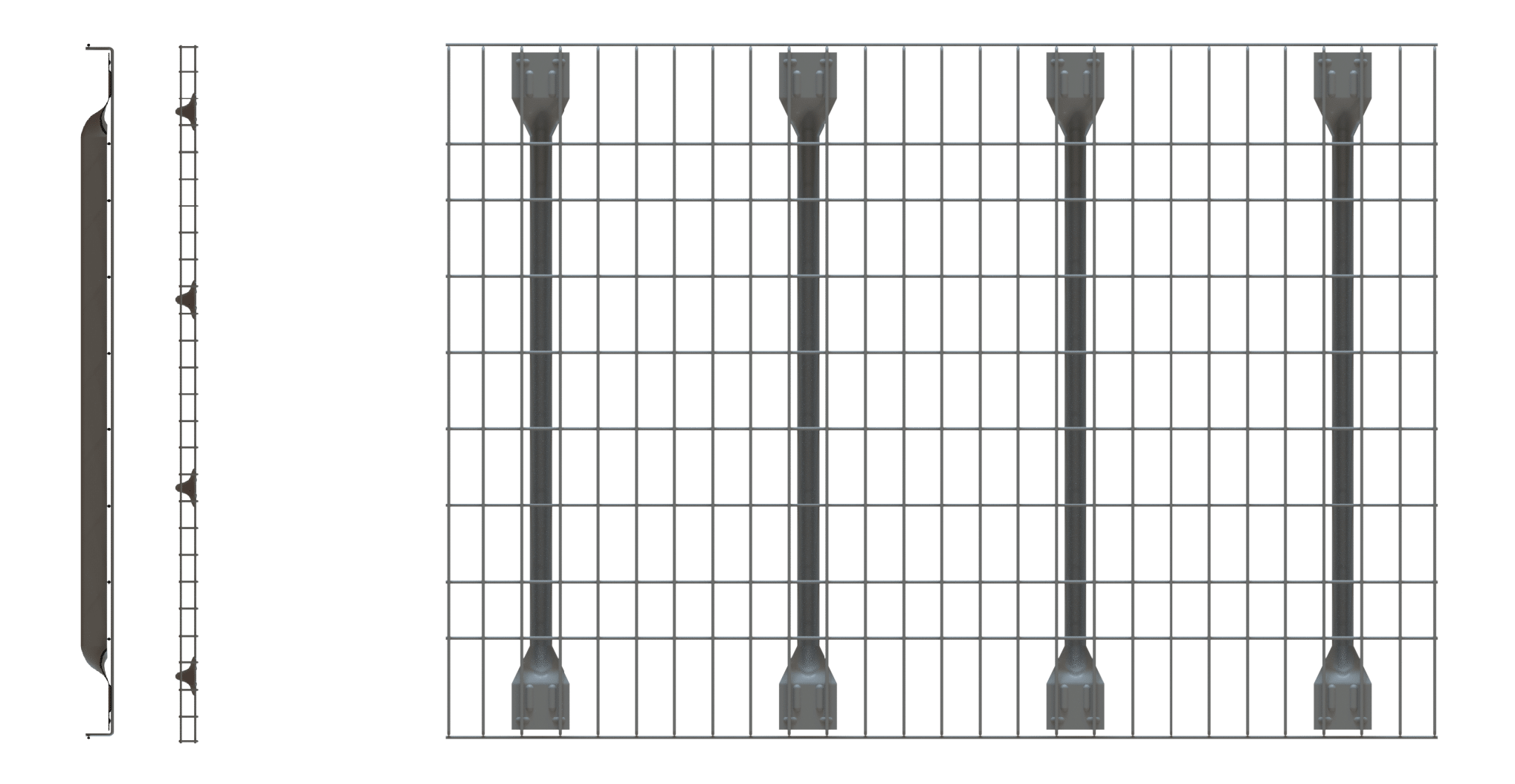

Looking for durable, powder-coated wire mesh decking for pallet racking? Our easySHELF™ Powder-Coated Stock Decks are available in the most common bay sizes for quick, clean, and reliable installations. Manufactured with 4mm wire and featuring 3 or 4 support bars, these decks are ideal for indoor warehouse environments where both appearance and performance are important.

SPECIFICATION

55x100mm mesh aperture

4.6mm Wire Thickness

3 – 5 support bars

(depending on weight loading)

Maximum weight loading 1000kg or 1500kg

Powder coated finish

RAL7042

Why Choose Powder-Coated Mesh Decks?

- Fast Lead Times: 5–10 working days UK-wide

- Cost-Effective: Great value for long-term durability

- ESFR Compliant: 70% open surface for fire safety compatibility

- Aesthetic Finish: The perfect finish for a customer-facing warehouse

- Light-Friendly: Increased visibility and sprinkler access

- Fits Most Racking: Designed for all popular bay widths

The Powder-Coating Process

Firstly, the product undergoes a pre-wash stage and then enters the wash plant, where unwanted chemicals such as rust and grease are removed from the steel. The mesh then enters a dry-off oven, which heats the metal to approximately 160°, allowing the powder to adhere more effectively.

Now that the product is prepared, it can be sent into the powder booth. The product itself is positively charged, while the powder is negatively charged, which causes it to adhere to the surface of the metal. The product then enters the curing oven. The heat bakes the powder, allowing it to set.

Quote to Site®

Order Direct from Quote to Site®

You can now order powder-coated mesh decks directly through our digital platform, Quote to Site®. Select your sizes, enter your delivery postcode, and receive a quote in minutes. No waiting around.

- Fast & accurate quotes, anytime

- Real-time pricing with instant PDF downloads

- Ideal for standard or multi-site projects

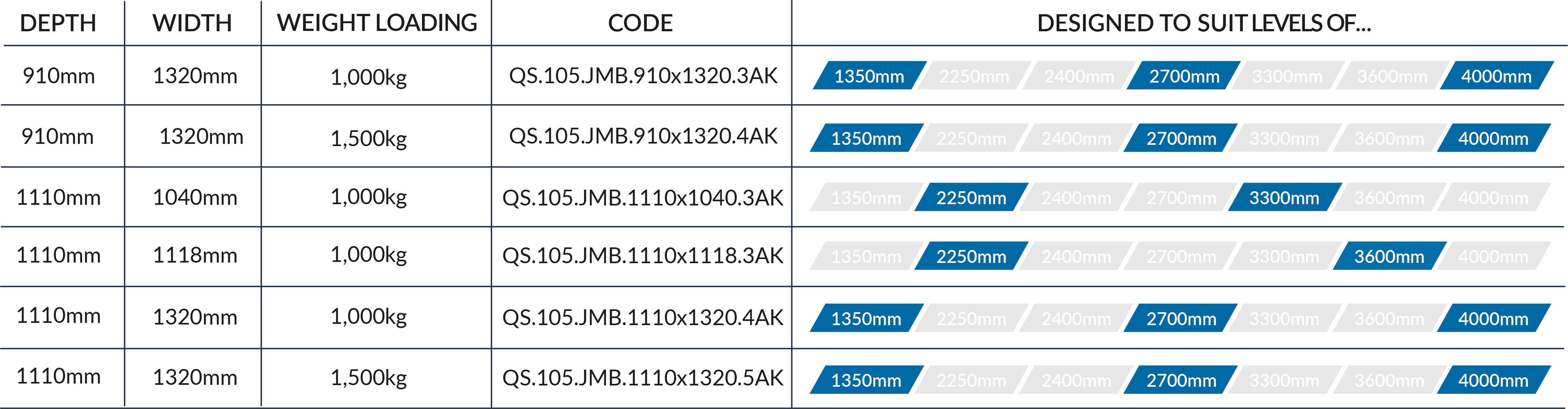

AVAILABLE SIZES

*Please note: Subject to availability. Large orders will be factored into our production plan and a lead time will be given accordingly.

*The bay will usually need to be split into multiple mesh decks. For example, a 2700mm bay will need 2x QS.105.JMB.910×1320.3Ak decks